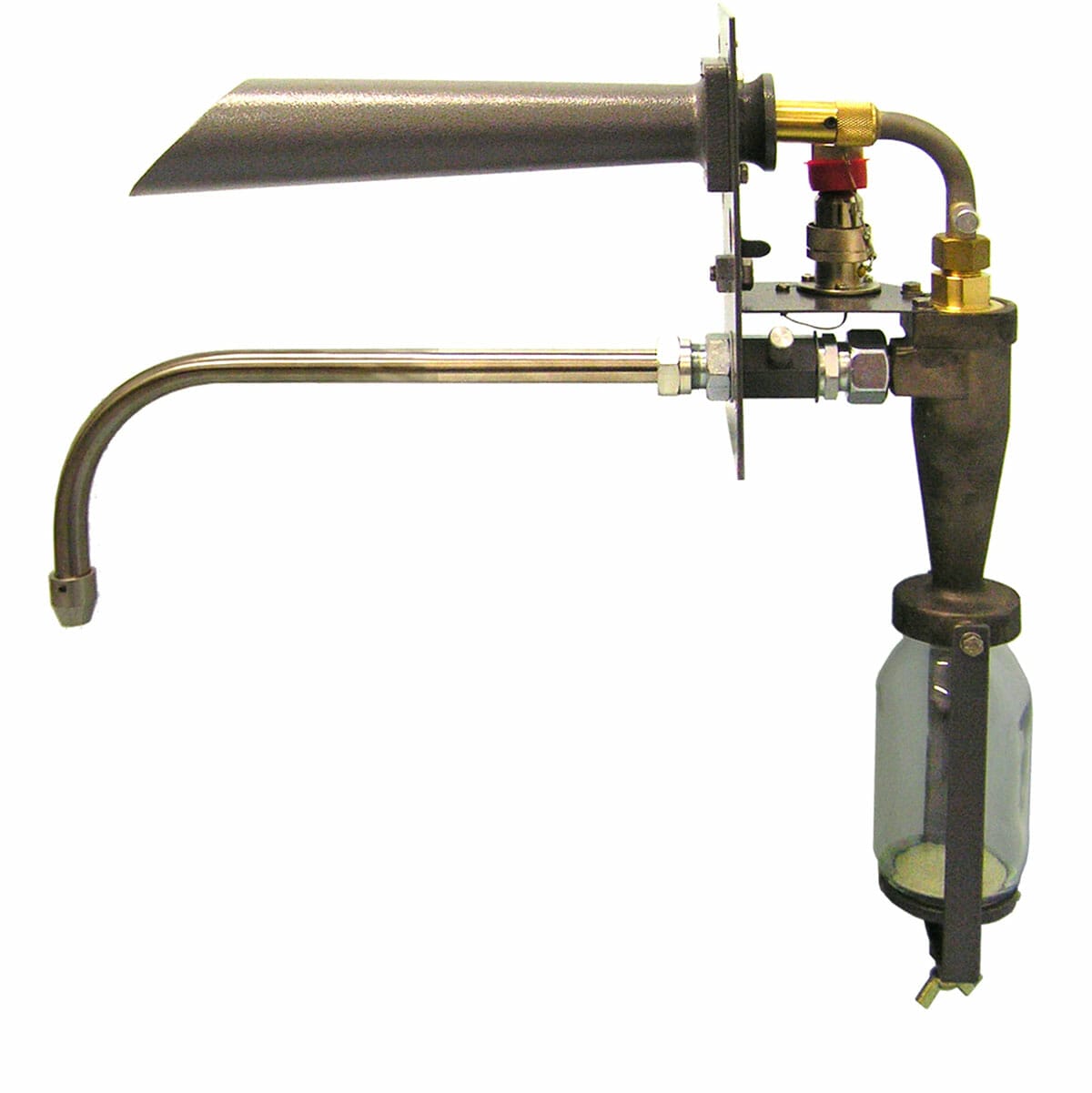

The Kanomax Piezobalance Dust Monitor 3521/3522 is a unique respirable aerosol monitor, providing direct mass concentration of particulates using PIEZOBALANCE technology; ideal especially for oil mist monitoring. The Kanomax 3521 is equipped with 4 and 10µm impactors while the 3522 is equipped with a 2.5µm impactor. Unlike conventional dust meters, which count particles, a piezobalance dust meter like the 3521 or 3522 “weighs” mass concentration of particulates. As an air sample enters the system, it travels through the impactor, which captures and removes larger particulates away from the sample. Smaller particulates become electrically charged and deposited on the piezo-crystal. The total mass of the deposited particulates affects the piezo-crystal’s frequency. Since the change in frequency is proportional to the mass of the particulates, the actual weight of the particulates is obtained.

More Information

Navigate the tab section below to see this product’s Features & Benefits, Specifications, Resources, and more.

- Measures PM 10, Respirable, or PM 2.5 particle matters

- Real-time measurements of dust concentration

- Data logging up to 500 measurements

- Simple cleaning mechanism for easy maintenance

- Complete with data processing software, RS 232C cable, cleaning kit, Ni-MH battery pack, AC adapter, carrying case and calibration certificate

- Oil Mist Monitoring

- Automotive Engineering Area Monitoring

- IAQ Investigations

- Industrial Hygiene

- Occupational Health & Safety

- Product Quality Control

- Laboratory Research

| Main Unit Specifications | |

|---|---|

| Model | 3521 |

| Measuring Object | Airborne Particle Matter 0.1 to 10 µm |

| Impactor | 10 µm, 4 µm |

| Measuring Range | 0.01 to 5 mg/m3 |

| Accuracy | +/- 10% of reading +/- 1 digit (0 to 5 mg/m3) +/- 20% of reading +/- 1 digit (5 to 10 mg/m3) |

| Model | 3522 |

| Measuring Object | Airborne Particle Matter 0.1 to 2.5 µm |

| Impactor | 2.5 µm |

| Measuring Range | 0.01 to 10 mg/m3 |

| Accuracy | +/- 10% of reading +/- 1 digit |

| General Specifications | |

| Sampling Flow Rate | 1 L/min |

| Datalogging | 500 data and time stamped measurements |

| Interface | RS-232C |

| Power Supply | Ni-MH battery or AC adapter |

| Dimensions | H7.0″ x D5.9″ x W2.7″ (180 x 150 x 65mm) |

| Weight (with batteries) | 4.4 lbs. (2 kg) |

| Warranty | 1 year |

| What’s Included | Meter, Operation manual, Software, RS232C cable, AC adapter, NiMH battery pack, Cleaning kit, Impactor(s), Carrying case, Calibration certificate |

User Manual

Data Sheet - English

Application Note - Dust Monitoring Methods

Software Manual

- Portable Printer: Model DPU-S245

- Portable Printer Paper: Model TP-5RLPK

- Piezobalance Dust Monitor NiMH Battery Pack: Model 3521-01

- Piezobalance Dust Monitor Cleaning Sponge: Model 3521-06

- Piezobalance Dust Monitor Cleaning Fluid: Model 3521-07

Kanomax Piezobalance Dust Monitor - Overview

Our sales representatives are here to help you find the right instrument for your application. Fast.

Request a quote today to find the product you need with expert assistance.